Wonderous Engineer's Stories

Everyone picks up a few funny stories over his career. Here some I've lived through from behind the console and some I've picked up:

Sauce for the Goose...

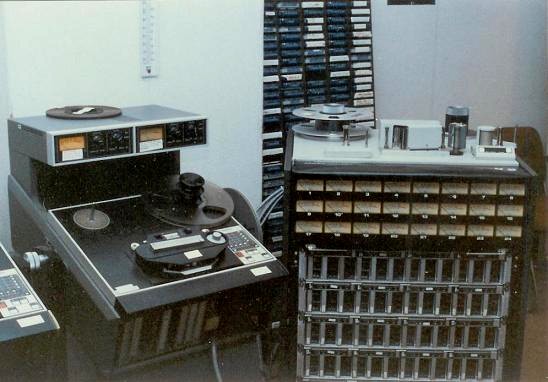

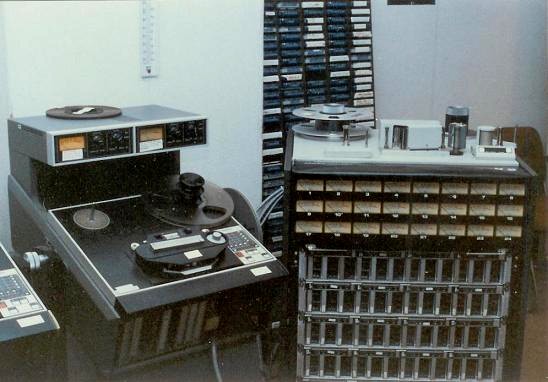

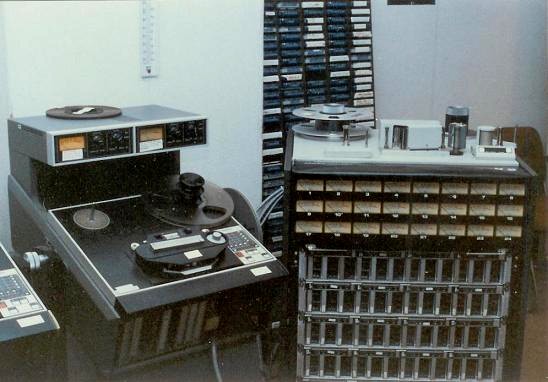

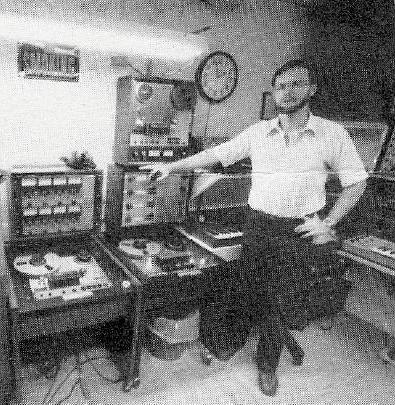

The ATR-102 in question is on the left with the Y-cord visible at the bottom.

That's an Ampex MM1200 "Master Muncher" 24-track on the right.

During the late 1970s and the 1980s, the Ampex ATR-100 series analog tape transports were simply the most stable professional audio recorders available. They handled like a dream and sounded wonderful. Because of its revolutionary all-servo design, their transport could be cued with two fingers by moving a knob on top of the center "biasing" motor. The design has survived into this century as the most sought-after analog two-track recorder of all time.

Early ATR-100 cueing knob

The early ones were hand-turned, the later ones cast

Courtesty Michael Spitz at ATR Services

The facility in which I worked as a staff recording engineer had about eleven of these machines and my audio post control room was home to three of them. One of these was modified to allow it to be used with our second generation EECO synchronizer and synched to SMPTE time code. In order to allow both synchronizer and manual remote operation from the console, the modified machine was rigged with a multi-way “Y-cord” on the remote jack. This machine was occasionally moved to other suites by maintenance engineers for use in SMPTE operations. Typically, when it was returned, the engineers handled reconnecting it.

Now Ampex wisely fitted the machine and its remote cable with keyed multi-way edge-card connectors to make it impossible to connect the cables backwards. Sadly, our company’s engineers only had un-keyed connectors on hand when they built the Y-cord. Rather than incur extra expense, they used what was on hand. When they first delivered the Y-cord and plugged it up, I saw the problem and marked each of the connectors with tape so that the plug’s proper polarity was obvious.

One day when the engineers returned the machine from another control room, they left it with the Y-cord dangling, disconnected. When I needed the ATR for an immediate session I had to plug it up myself, and this was when the fun began. Somehow, my tape labels had been scraped off the connectors so they didn’t give me a clue as to which way to plug them. I took out a green tweaker screwdriver, removed the dress covers from the Y-cord connectors, and tried to trace the wires in the rats nest. Unfortunately, the engineers hadn’t followed the Ampex wire-color standards so there was little hint. I made my best guess, connected the cables, and switched on the power.

POOOF!!!

A minor explosion issued forth and a cloud of acrid, sulfuric smoke shot out of the machine and headed for the ceiling. Oh, boy! I marshalled myself, called engineering, explained the problem and the un-keyed connectors, and prepared to eat a big helping of crow. The engineers retrieved the machine, shaking their heads and clucking at my stupidity. For two weeks, whenever an engineer saw me, he'd give me the "Oh, THERE'S the murderer!" look. Two weeks later, an engineer brought up the machine and dropped it off. Putting on his most patient, parental face, he said, “I think you ought to know that I spent every minute of my time for the last two weeks getting this machine back up. Your mistake blew fifteen integrated circuits in this thing and they masked each other's failures hierarchically. I would discover and replace one and a blown IC upstream would cause the replacement to blow again. I would find the second one, replace both, and a blown IC upstream of both would blow both of them again, and so on. You cost us a lot of time and components! You really MUST make sure the connectors are plugged up with the correct polarity!”

As he turned to leave, I noticed that the cables weren’t plugged up to the Y-cord again and decided to play dumb. “Um, uh... I think this might just be beyond my expertise. Could you hook the connectors back up for me?”

People love to feel superior. The engineer picked up the cables and for the first time, noticed they weren’t keyed OR marked. He took out a screwdriver and removed the dress covers from the Y-cord connectors. Scratching his head, he tried to trace the wires. Hmmmmm... Eventually, he made his best guess, connected the cables, and switched on the power.

POOOF!!!

A minor explosion issued forth and a cloud of acrid, sulfuric smoke shot out of the machine and headed for the ceiling. I tried my best to keep from giggling. Two weeks later, I got the machine back with no comments and permanent labels.

YES performs Soon, July 2000

The Amazing Dancing Musicians

Way back in the late ‘70s, I took a contract from a promoter with a tight budget to supply PA services for a concert by a national act. To save money, he requested that I undertake the engineering solo, with a single console handling both the house and monitor mixes. The band arrived at the hall and set up. They seemed cool enough and we got the house and monitors going pretty quickly during the sound check. During the concert, I gave them a clean mix with no feedback or apparent problems. Just before the last song, the guitarist for the band took a moment to thank the promoter and hospitality folks, then looked back to me and added, sarcastically, “Oh yea, and thanks to Bob on feedback.”

My surprise was so great that without any thought, and seemingly of its own accord, my hand shot out and shoved the monitor master fader all the way to the top. The entire power of the monitor system's amps was instantly delivered to the monitor speakers, and they responded by generating an incredible low-frequency feedback rumble like the sound of an accelerating diesel locomotive passing at close range. The stage heaved. The mic stands and band shook violently as amplifiers and gear danced across the stage. When I regained control of my hand, I snapped the monitor master back down.

The band's guitarist looked around sheepishly and said, “Gee, I guess that’s someone you don’t want to offend.”

Perfectionism can eat you up...

The vibrating amps remind me of a conversation I had with the ex-monitor engineer for the band AC/DC, regarding a time when they were playing a few dates with the band Boston. Now, please understand that I like Tom Scholz and Boston really well but this is still a funny story...

AC/DC's crew discovered that for part of his sound, Tom Scholz, lead guitarist, producer, and mastermind of Boston was running his guitar through a mic'd up Fender Twin Reverb amp suspended in a spring isolation frame, located in an offstage room. Tom would spend HOURS during sound checks, tweaking things to "get it right", and supposedly driving everyone crazy.

This fellow said they would sneak in and slap the Twin to create spring reverb crashes during the sound check performances and then retire to stageside to watch Tom loosing his marbles trying to find the problem.

Uncommon Common Sense

One night in the mid-eighties, I was running a great monitor system for a combined ticket with a local seven-piece band as the warmup for a national solo performer, Larry Norman. It was a good audience and a great venue. The seven-piece band was the usual big deal with multiple mixes and making everyone happy. When it came time to bring on the solo artist, just Larry and his guitar, he came over to me and said, "You know, I really don't need any monitors. You can take a break." I said, "Well okay, tell you what. I'll put 'em up low and if you don't want 'em, let me know after the first number." He agreed and took the stage. After the first number, he asked for a couple of changes from the house engineer and then turned to me with a smile and said, with a touch of irony:

"Okay, I can hear myself fine so I you can kill the monitors. AFTER ALL, I'M STANDING RIGHT NEXT TO ME."

The Good Old Days

Let's talk about "manly men's tape machines" from "the good old days". I'm referring to the console tape decks with twenty-pound AC-induction motors under each reel turntable, a brake system from a Volkswagen Beetle, massive reel locks to keep control of the tape reels, and genuine ruby tape guides. Real chest-thumping stuff here! These monsters were easily capable of removing chucks of skin or even digits from unwary operators when they were in fast-wind modes.

Ampex 440C Four Track

Machines of this period had no transport logic, meaning that they entered into whatever mode you selected directly. You couldn't go from fast forward to stop: The machine would instantly screech to a halt, stretching and breaking your precious tape, or possibly doing worse. You had to slow down the tape by hitting rewind then waiting for the instant when the reels came to rest before hitting stop. It was referred to as "jockeying the reels" and required nimble fingers on the controls. Watch an old pro sometime and see whether he's lost this habit...

I remember an interview at a studio, early in my career. The chief engineer of this facility had the funny habit of asking each applicant his birth month so he could figure his astrological sign. When he heard that I was born in April, he eyed me warily. At some point he he said, "Oh, I suppose I can try letting another Taurus in my control room. But let me tell you what the last one did to me."

The young lady to whom he referred (Manly yes, but I like it, too...) was taking down a project from the Ampex 440C, one-half-inch deck, and forgot to hit rewind to slow things down. The instant she touched the stop button, right near peak fast-wind speed, the right-hand reel lock failed due to excess torque. In the blink of an eye, lock and reel departed the turntable and headed out across the control room, breaking off an adjacent tape machine's three-eights-inch steel capstan shaft and tensioning arm. The heavy reel zipped by the young engineer's face like Odd-Job's hat. It transited the control room and ricocheted off the corner of the console's meter bridge, shattering three meters. At this point, the young engineer-to-be wisely elected the better part of valor and dived for cover under the console. The nearly-full reel of one-half inch tape continued on its merry way around the room like a frisbee on steroids, slinging a stream of half-inch tape behind it. By the time the reel's kinetic energy was exhausted and the ricocheting stopped, something on every wall of the control room had been broken or nicked and the entire floor was filled two inches deep with audio tape.

From then on, the dings on the walls were carefully preserved and the remains of the failed reel lock hung over the tape deck with a note as a reminder to all of the destructive power of a mishandled tape deck. After enjoying a couple of negligent episodes of my own, I, for one, still haven't completely lost the habit of jockeying the reels, even though I work mostly on virtual transports!

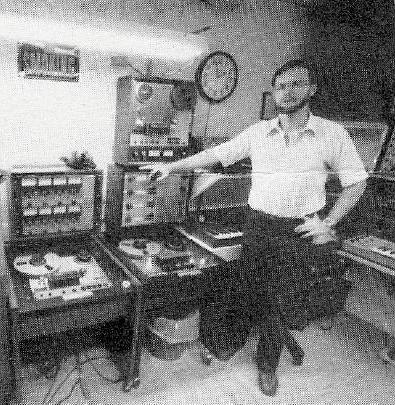

Ken has his hand on the machine in question.

= =

=